RCM offers spray injection patching services for pavement repair and maintenance. We’ve specialized in this process for over 25 years. Spray Patching, is the most cost-effective, longest lasting method to repair: Potholes · Alligator cracks · Cup cracks · High iron · Sink holes · Catch basins · And more!

Superior Spray Patch System

Spray injection patching is a specialized repair process that combines hot asphalt emulsion and crushed aggregate using forced air. Spray injection patching is very versatile in the types of repairs that can be done! It is not only an exceptional repair method for potholes, you can repair alligator cracks, cupped cracks, areas that are raveling, high iron and any other type of repair were you would use traditional asphalt. This type of repair can easily be used on concrete.

What Equipment Do I Need?

The spray patch equipment consists of an aggregate hopper, hot asphalt emulsion tank and a high volume blower which is all mounted on the same piece of equipment. There are two types of machines: Trailer mounted and Truck mounted. The trailer mounted machine takes a 2 to 3 person crew to operate the equipment; the truck mounted machine needs only one person to operate the equipment.

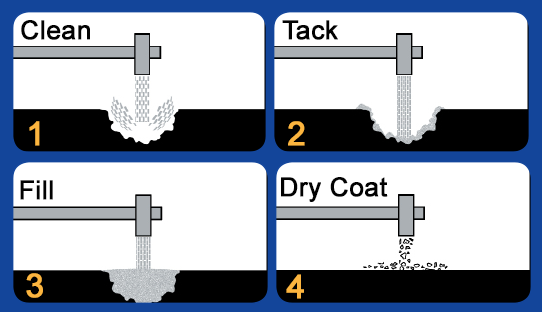

How Does it Work?

The mixture aggregate/emulsion mixture is injected into the pothole with forced air. This is a permanent repair, it can be done year round and traffic can flow immediately on to the repaired areas. Due to the fact that we are applying a tack coat of "HOT" emulsion prior to making the repair, we are ensuring that water will not seep back into the repaired area causing more damage.

What About the Weather?

Cold weather is when the cost savings really start to add up. The repaired area will withstand the freeze thaw movement of pavement. It does not deteriorate or break out. There are not hard edges for the snow plows to catch the patch and it will stay in place. Even when the temperature is below freezing, you will not have to go back time and time again to the same pothole.

Are There Cost Savings?

The cost savings is apparent right from the start, 2 men is all that you need to place approximately 8 tons of material with the trailer patcher while 1 man can place 12 tons of material with the truck.

How Safe?

If safety for your workforce is a concern, the truck mounted unit is the answer! One man can work from the safety of the cab and still place approximately 12 tons of "HOT" material. The trucks are equipped with their own arrow-board and a crash cushion can be easily added.